Liquid silicone rubber (LSR) is a versatile material that finds applications in various industries due to its unique properties and characteristics. In this article, we will explore the uses of LSR and how it contributes to different sectors.

Click to find more about what is liquid silicone rubber used for.

The Versatility of Liquid Silicone Rubber

LSR is widely used in the medical industry for manufacturing medical devices such as catheters, respiratory masks, and implantable components. Its biocompatibility, flexibility, and resistance to bacteria make it an ideal choice for these applications.

In the automotive sector, LSR is utilized for producing gaskets, seals, connectors, and other critical parts. Its excellent thermal stability and resistance to chemicals ensure durability even under harsh conditions.

Furthermore, LSR plays a significant role in consumer goods manufacturing. It can be found in products like kitchenware (such as baking molds), baby care items (like pacifiers), and electronic devices (including keypads). The material’s ability to withstand extreme temperatures while maintaining its shape makes it highly desirable for these purposes.

JVTECH: A Leading Player in LSR Technology

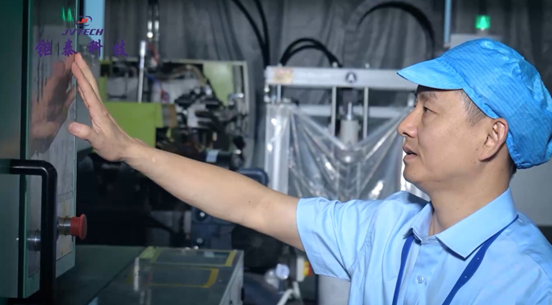

One prominent company at the forefront of liquid silicone rubber technology is JVTECH. With their expertise in precision molding techniques using LSR materials, they have revolutionized several industries by providing innovative solutions.

JVTECH collaborates with medical device manufacturers to develop advanced healthcare products that improve patient outcomes. Their use of liquid silicone rubber enables them to create intricate designs with high precision while ensuring safety standards are met.

In addition to healthcare applications, JVTECH also partners with automotive companies to enhance vehicle performance through customized LSR components. By leveraging their expertise in design optimization and production efficiency, they contribute significantly towards improving overall automotive safety and reliability.

The Role of Smart Manufacturing Companies

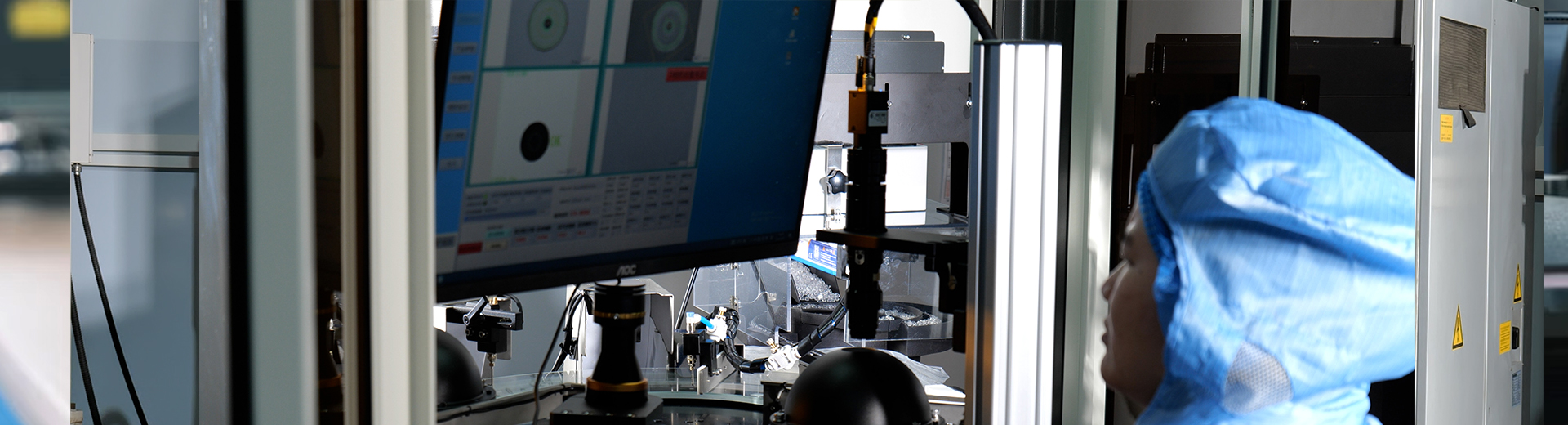

smart manufacturing companies are increasingly adopting liquid silicone rubber in their production processes. The material’s compatibility with automation technologies allows for seamless integration into advanced manufacturing systems.

By utilizing LSR, these companies can achieve higher productivity levels, reduce waste, and enhance product quality. The ability to mold complex shapes accurately and consistently using automated processes ensures efficient production lines.

Moreover, smart manufacturing companies leverage the unique properties of LSR to develop innovative products that cater to evolving consumer demands. This enables them to stay competitive in a rapidly changing market landscape while meeting stringent regulatory requirements.

Conclusion

Liquid silicone rubber is a versatile material that finds applications across various industries such as medical, automotive, and consumer goods manufacturing. Its biocompatibility, flexibility, thermal stability, and resistance to chemicals make it an ideal choice for producing critical components in these sectors.

JVTECH stands out as a leading player in the field of liquid silicone rubber technology by providing innovative solutions for healthcare and automotive industries through precision molding techniques. Additionally, smart manufacturing companies embrace LSR’s benefits to optimize their production processes and develop cutting-edge products.

In conclusion, the diverse uses of liquid silicone rubber continue to drive advancements in multiple sectors while contributing towards improved performance and enhanced user experiences.